- Canon Community

- Discussions & Help

- Printer

- Professional Photo Printers

- Re: Pro-10 From paper issue to banding issue

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Pro-10 From paper issue to banding issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 05:11 AM

The paper issue was when using glossy, the papers I have were doing some curling, and teh edges would get ink all over them. so I curled the edges and this helped. But this happened about 10 times and a couple times the paper got hit and the printhead dragged across it. SO I raised the printhead in the Custom settings. And this degraded printing. I lowered it and stopped using that paper. Went to normal paper and then the banding started.

I have done normal and Deep cleaning cycles, I have printed nozzle check after nozzle check and print checks, and they are NOT looking great.

I have gone through 2 sets of ink tanks ($140 each set), about 25 sheets of excellent 13x19 paper, and over 2 days of time.

Last resort I took out the print head and put it in a water/amonia/alcohol bath for a couple hours. Also squirted water (distilled) on the head and inside to clean up. Inserted and still NOT ok. I get the banding. Its 2AM, and I am still up and working on this printer as the 3rd day. I wonder what could be the issue?

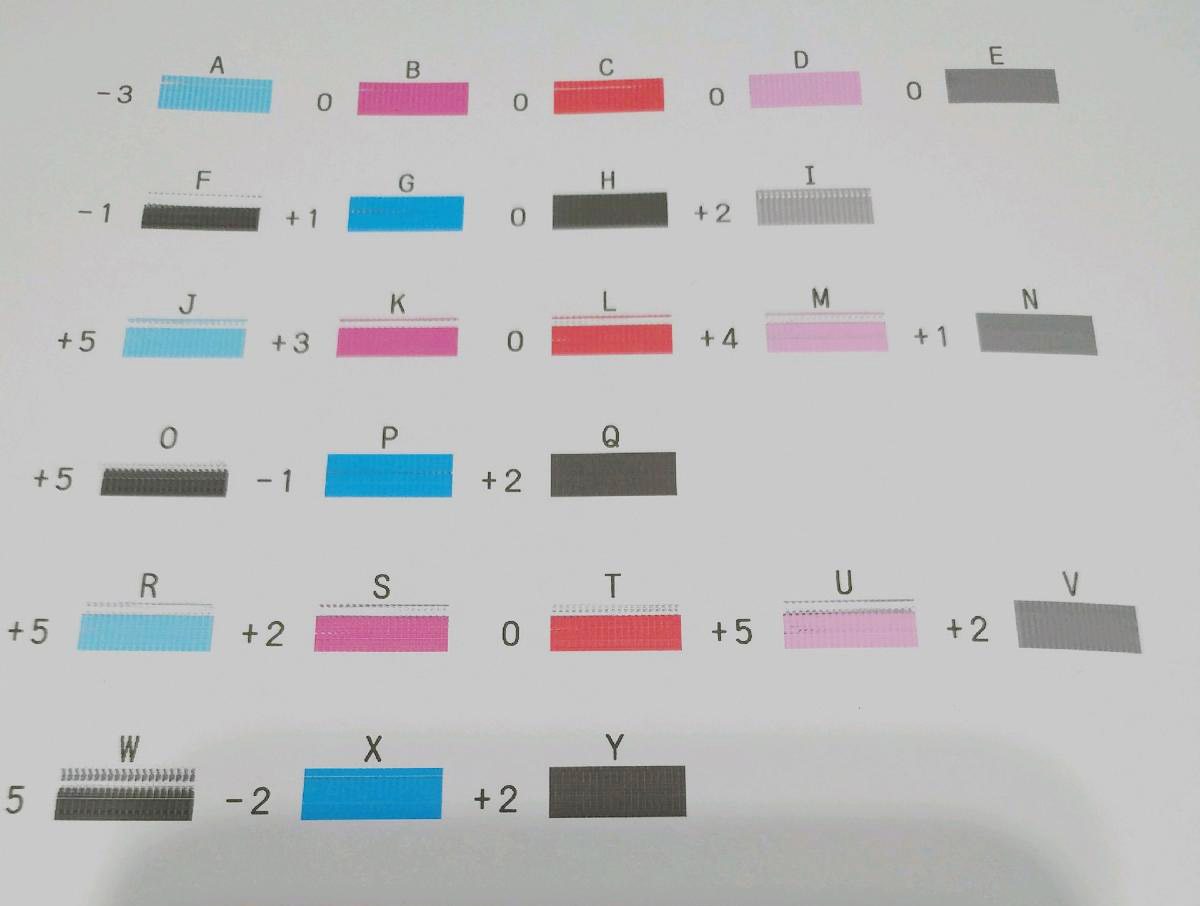

I am at this point lost on what could be the reason. Some fibers it picked up from the paper strikes and is not coming off, or? But most are effected, not just one color. I honestly cannot make sense in reading this chart as I see ABCDE are bad, then I see F is horrible, and G has slight gaps, H is a bit better, and I is bad. J is bad, K, L,M, N are bad. O is almost half empty, P is not bad, same with Q, they are pretty OK, very slight gaps.RSTUare gapped, with U missing a line, and V is missing more. Wand X are missing a slight line, Y is not so bad.

Not sure what the values are saying for each row.

-3

-1

+5

+5

+5

+5

At first I had issues doing manual alignment. I figured how to do it, and I made the adjustments, and this too did not clear the issue. I switched back to auto align.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 07:09 AM

In my opinion you have a print head problem.

Until/unless you can get proper nozzle check patterns any other efforts are going to be futile.

Conway, NH

1D X Mark III, M200, Many lenses, Pixma PRO-100, Pixma TR8620a, Lr Classic

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 01:38 PM

WHat does the problem look like? Considering that the head was getting caught on the paper edge, and it was a 286gsm paper that it did damage the paper a slight bit, as it pulled less than a MM of the coating ..Could that have damaged nozzles?

Perhaps I will take the head out one more time and do a much more thorough cleaning with the WaterPik. But if I am pushing paper fibers back into the head behind the nozzles, they will come back to the nozzles. so, maybe a pressureized wash so it comes out the other end? But the other end where the inks sit is the rubber gasket and a sponge like oval area ...where I think the ink enters from. Maybe I need to remove these foam ovals off each ink and then do the flush?

Or buy a Pro-300 print head

?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 01:43 PM

I have a steamer, I can try that, or a warm to semi-hot solution bath. sit for hours, or longer, and then the waterpik, then flush out from nozzle to exit from ink tank side. Unless I have another issue I am not aware of.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 01:44 PM

The Nozzle check patterns should look like solid boxes, NOT with lines, right?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 02:37 PM

Conway, NH

1D X Mark III, M200, Many lenses, Pixma PRO-100, Pixma TR8620a, Lr Classic

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 06:27 PM

This forum is pretty much you I take it? 🙂 well, thanks, but I guess this is not your area of knowledge with any depth. Wish me luck. I think the Pro300 is the same head, and they do sell a replacement fo rthat.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-01-2020 08:51 PM

>>I guess this is not your area of knowledge with any depth<<

Don't underestimate jrhoffman75. He is by far the most useful contributor to this forum and has solved innumerable problems for users of Canon professional photo printers. He is our most valuable member.

Robert N.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-02-2020 04:21 PM

I do appreciate his input, and I didn't mean it to sound unappreciative. I am just being blunt with my issue and so far while he is the only one with a few suggestions, this last comment was kinda what made me a bit perplexed, as the entire time we are dealing with the printhead, and maybe the image needs to be larger to see the nozzle check better or, something.

But I am guessing this is a rare occurance(People having paper with curl edge)?

I have to accept that...So he maybe stumped and felt to say something, but the obvious didn't help.

Someone mentioned that if my encoder strip is dirty it will never be able to do a alignment. But its a channel with no focus, so its been days, and that person may never return to it. I see the encoder strip, or at least what I think is the encoder strip, the "clear" film that runs along the with the belt. So if I know how to access that strip, I maybe able to check.

The printer is lightly used (got it new 2 years ago), and I have done about 500 total prints on it, including basic ship labels on standard paper, and many other receipts with 5% coverage. But recently did about 40 prints. I also notice the CO channel maybe clogged. I get out of ink, but there is nothing actually checking the ink, it is software calculated, as the ink tank of my CO drops about 5 grams and it thinks it is out.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

11-02-2020 04:22 PM

Ya, that was a bit snide. Sorry. Just frustrated...and feel like this is part of 2020 on a personal level.

12/18/2024: New firmware updates are available.

EOS C300 Mark III - Version 1..0.9.1

EOS C500 Mark II - Version 1.1.3.1

12/13/2024: EOS Webcam Utility Pro V2.3b is now available to support Windows on ARM PC users.

12/05/2024: New firmware updates are available.

EOS R5 Mark II - Version 1.0.2

11/14/2024: Windows V 2.3a installer for EOS Webcam Utility Pro is available for download

11/12/2024: EOS Webcam Utility Pro - Version 2.3 is available

09/26/2024: New firmware updates are available.

EOS R6 Mark II - Version 1.5.0

08/09/2024: Firmware update available for RC-IP1000 - Version 1.1.1

08/08/2024: Firmware update available for MS-500 - Version 2.0.0

- PIXMA G3270: Won't print complete page in Desktop Inkjet Printers

- Canon Pixma ix6820 showing "Offline" or "Other" Errors in Desktop Inkjet Printers

- imageCLASS D570: Battery replacement error in Office Printers

- imageCLASS MF656Cdw does not scan in Office Printers

- Pixma Pro 10 Lined area in Professional Photo Printers

Canon U.S.A Inc. All Rights Reserved. Reproduction in whole or part without permission is prohibited.