- Canon Community

- Discussions & Help

- Printer

- Desktop Inkjet Printers

- Canon G3501 printing/ink supply issues

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

01-18-2023 06:34 AM

My G3501 worked flawlessly until this summer, when we were away from home for two weeks. When we came back, it wasn't printing magenta at all. I did cleaning, deep cleaning, nothing helped. I took out the printer head and pushed some ethanol/distilled water solution through it with a syringe and this fixed the issue.

A few weeks later, the printer was playing up again. I opened the printer and saw that there was air in the ink tubes. I cleaned both print heads with a cleaning solution. I also used a syringe to pull ink back to the print head tray and everything was OK after a few prints.

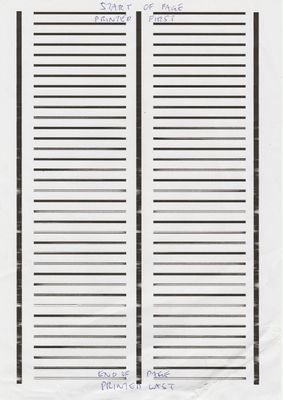

Now this week the black ink was playing up and there was a little air in the black tube. I clamped all the tubes, removed the black print head, pulled the ink back, put the head in, un-clamped the tubes and did some test prints. Now it seems like there is only enough ink supply for the beginning of each print session, then the ink supply doesn't keep up. I printed this test page:

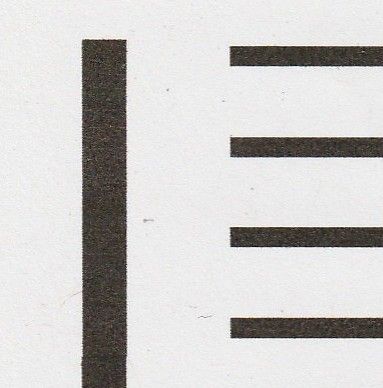

Here are detail crops from the section printed first by the head and the section printed last:

As you can see, the black is almost perfect at the start and then it deteriorates.

I am now wondering if there can be some obstruction earlier in the ink supply, somewhere at the ink tank or between the ink tank and the tubes, that makes for poor ink supply and also leads to air intrusion in the tubes. As the problem started when it was quite hot this summer and the printer was unused for several weeks, it seems plausible that it relates to ink drying out in some part of the printer.

Has anyone else experienced anything similar?

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

01-27-2023 10:26 AM

UPDATE:

Printing has now returned to normal, after about 20 more "normal" print-outs. My conclusion is that even when the ink is fully returned to the tube and to the head, and with clean nozzles, somehow there is something (perhaps the level of pressure in the ink supply tubes) that still requires a number of print-outs to return to normal.

My advice to anyone else having issues with the Canon ink tank series is to keep a watchful eye on the ink tubes, especially after opening the holder of the print head(s). As you do this, you break the seal between the ink tube and the ink entrance on the print head. This allows air to intrude into the ink tube and ink retreats towards the tank. When you then close the head assembly again, you can try as much as you like to run printing, cleaning and even deep cleaning – without a continuous path of ink all the way into the head, you will have issues.

The only way to deal with this is to use something to clamp the ink tubes before opening the head assembly, to prevent the ink from retreating. If necessary, unclamp and use a syringe to pull ink back all the way until you have no air in the tubes. Then only remove the clamps after the assembly is shut closed so that the tubes seal against the head ink openings.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

01-27-2023 10:26 AM

UPDATE:

Printing has now returned to normal, after about 20 more "normal" print-outs. My conclusion is that even when the ink is fully returned to the tube and to the head, and with clean nozzles, somehow there is something (perhaps the level of pressure in the ink supply tubes) that still requires a number of print-outs to return to normal.

My advice to anyone else having issues with the Canon ink tank series is to keep a watchful eye on the ink tubes, especially after opening the holder of the print head(s). As you do this, you break the seal between the ink tube and the ink entrance on the print head. This allows air to intrude into the ink tube and ink retreats towards the tank. When you then close the head assembly again, you can try as much as you like to run printing, cleaning and even deep cleaning – without a continuous path of ink all the way into the head, you will have issues.

The only way to deal with this is to use something to clamp the ink tubes before opening the head assembly, to prevent the ink from retreating. If necessary, unclamp and use a syringe to pull ink back all the way until you have no air in the tubes. Then only remove the clamps after the assembly is shut closed so that the tubes seal against the head ink openings.

03/18/2025: New firmware updates are available.

EOS R5 Mark II - Version 1.0.3

02/20/2025: New firmware updates are available.

RF70-200mm F2.8 L IS USM Z - Version 1.0.6

RF24-105mm F2.8 L IS USM Z - Version 1.0.9

RF100-300mm F2.8 L IS USM - Version 1.0.8

RF50mm F1.4 L VCM - Version 1.0.2

RF24mm F1.4 L VCM - Version 1.0.3

01/27/2025: New firmware updates are available.

01/22/2024: Canon Supports Disaster Relief Efforts in California

01/14/2025: Steps to resolve still image problem when using certain SanDisk SD cards with the Canon EOS R5 Mark II

12/18/2024: New firmware updates are available.

EOS C300 Mark III - Version 1..0.9.1

12/13/2024: EOS Webcam Utility Pro V2.3b is now available to support Windows on ARM PC users.

11/14/2024: Windows V 2.3a installer for EOS Webcam Utility Pro is available for download

11/12/2024: EOS Webcam Utility Pro - Version 2.3 is available

- PIXMA MG3520 - will feed envelopes but not letter size paper in Desktop Inkjet Printers

- imageCLASS MF733Cdw - smudges & color issues in Office Printers

- PIXMA TS6320 - Not feeding Cardstock from rear in Desktop Inkjet Printers

- PIXMA MX922 Legacy Extension message and driver question and app question in Printer Software & Networking

- PIXMA MX922 -MP drivers will not install--no detection via USB in Printer Software & Networking

Canon U.S.A Inc. All Rights Reserved. Reproduction in whole or part without permission is prohibited.